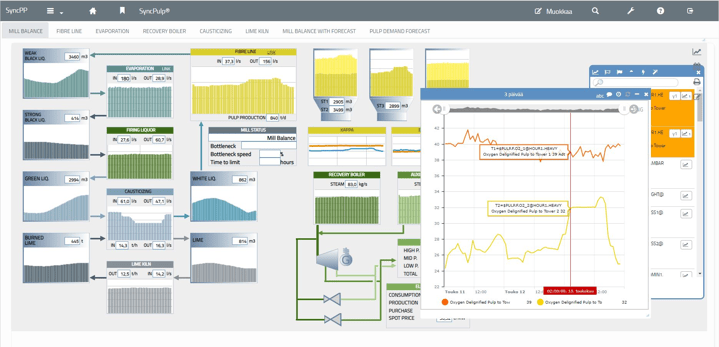

Operational control system for pulp mills and integrated pulp/paper mills.

SyncPulp® is a management and control system for the entire biorefinery, which enables even more agile operating methods. SyncPulp is based on long experience in the production and information system needs of the pulp industry.

The fundamental idea of SyncPulp is expanding the production perspective from production history and departmental optimization to anticipating the future and perceiving the whole. By steering the processes of the entire mill more visibly towards a common goal, significant improvements in production performance can be achieved.

SyncPulp is an easy-to-use browser-based application that enables data sharing and good remote access.

The system can be delivered as a service (SaaS), with no need for hardware investments, enabling a very fast delivery. SyncPulp includes built-in interfaces to most automation and data collection systems.

Our daily operations management product modules are Site-view, - production information displays and Diary - production's electronic logbook.

Copyright © Syncron Tech Oy 2023. All rights reserved. Privacy policy and Cookie policy. Cookie Settings.