Manufacturing execution system, monitoring and reporting in one and the same solution.

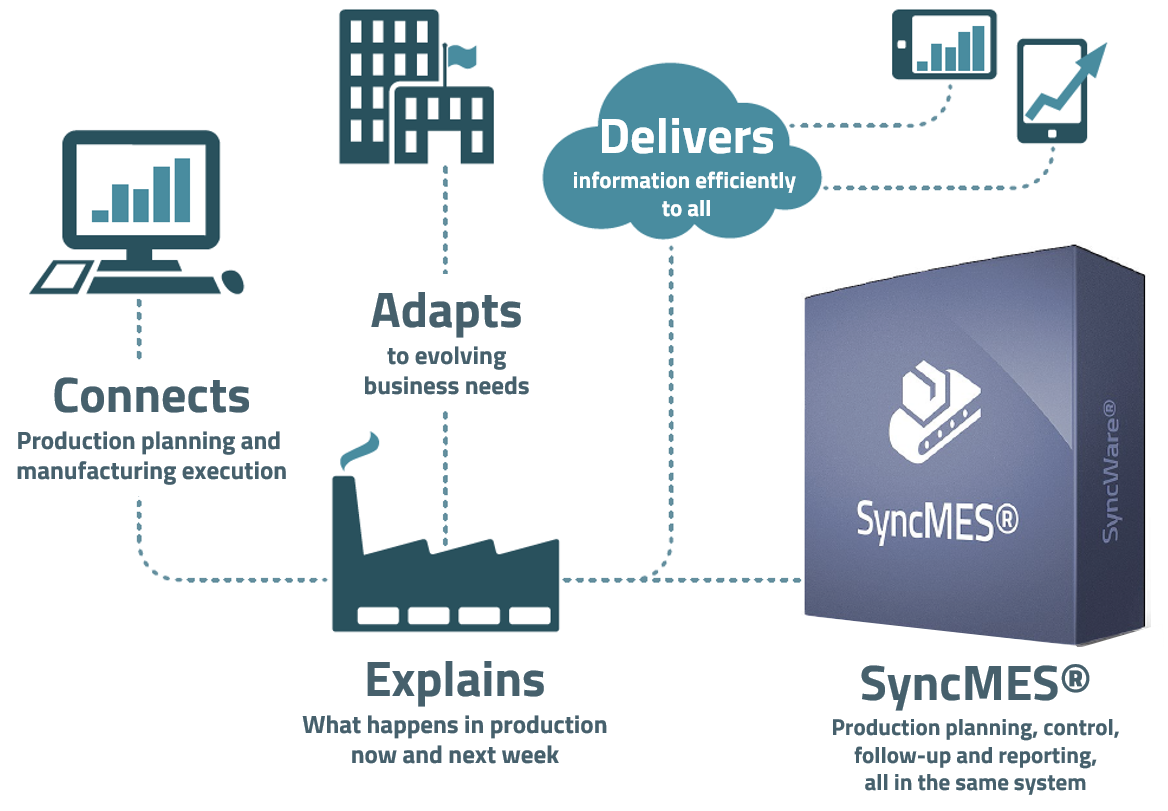

SyncMES® combines business information with measured process information. SyncMES® manages how production plans are executed and reports what and how much was produced.

SyncMES® adapts to the needs of different production processes. The MES system controls the production process and collects information about what, how and how much was produced. Although the basic functions of MES systems remain constant, the focus and scope of system features are determined by the production process. For example, there are different needs for managing goods, continuous and batch processes.

The MES-level system connects business and production processes. The connectivity of SyncMES® to ERP, BI, APS, Info, DCS, and other factory information systems is top class. The system's architecture supports efficient scaling, which makes changes made during the life cycle easy and cost-effective.

The SyncMES® user interface is a browser and it also supports mobile use.

Users of SyncMES® are typically all people involved in the factory's production, plant and production managers and planners, management and operators, customer service and those responsible for quality and maintenance.

The system produces role-specific relevant information for each user group for timely decisions.

Ease of use in an important feature.

Daily management tools/product modules are Site view - Information displays and Diary - Production's electronic logbook.

OEE and reports are also often counted in this group.

Often these have been implemented as independent functionalities. Other MES functionalities can be implemented later.