The most comprehensive set of solutions for the energy industry.

SyncPower® PLANT has a number of modules to manage power plant energy efficiency which help to improve power plant's production productivity and to reducing emissions.

SyncPower® PLANT can be used to combine data from different automation, process information, weighing and laboratory systems using versatile system interfaces. If necessary, data collection can be arranged with SyncIoT Edge data collection units directly from external measurement points, e.g. from district heating centers.

The most important modules are presented below.

At the commissioning of the operational control module, upper and lower limits are defined for power plant specific critical performance parameters. The limits typically change according to external conditions. The definition is done by statistically modeling the plant's best operational situations based on measurement data from previous production periods.

The operational limits and the process data are displayed in simple graphical trends and other visualizations. Operators keep the process in this optimal area. The modeling of operational control is based on process sub-balances. Top-level balances are boiler efficiency and power-to-heat ratio or specific heat consumption.

Operational efficiency deviations generate automatic alarms which are distributed using various methods for operators and managers. Real-time graphical operational control supports the user, enabling the best plant operation, consistently high efficiency and thus better operating economy. Operational control compares the change in operational situation to the optimal state. When focusing on the change, a significant part of the limited measurement accuracy and slow drift of the measurement devices can be eliminated.

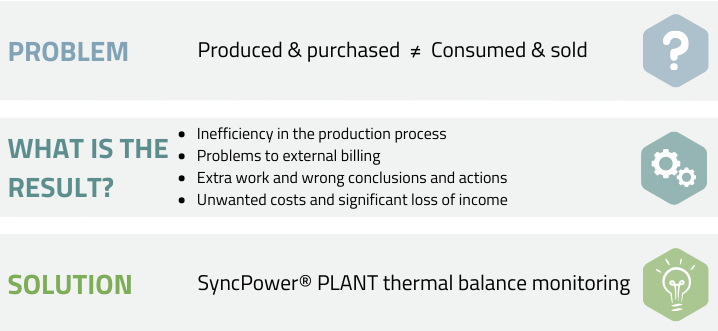

The thermal balance monitoring module resolves the balance differences of steam manifolds, eliminating the resulting billing problems.

Thermal balance monitoring is also known as steam manifold balance monitoring. When measuring the mass and energy flows of steam manifolds, it can often be seen that the energy produced and bought vs. consumed and sold differ. At worst, the difference in measurements causes uncertainty and problems in customer invoicing, which can result in loss of revenue. In any case, it results in inefficiencies in the production process, extra work, wrong conclusions, and other hidden costs.

With SyncPower® PLANT thermal balance monitoring, the mass and energy balances of steam manifolds at different pressure levels can be monitored continuously. SyncPower® monitors incoming and outgoing mass and energy flow amounts and balance differences. Measurements related to balance calculations and billing are constantly monitored. SyncPower® detects missing values, freezing and error readings of measurement data, creep of temperature measurements and enthalpy phase errors. The user of the thermal balance module has a visual graphical dashboard. Deviations generate alarms, which are sent e.g. via email, SMS, or to an alarm report of the module.

SyncPower® supports minimizing errors by reducing balance differences between incoming and outgoing flows and energies, reporting missing or low-quality measurements, and helping to identify measuring devices that need tuning. SyncPower® facilitates and increases confidence in energy billing.

(District heating and / or process steam)

In energy production, the optimization of an individual sub-process is rarely the best situation from the perspective of the entire production chain. A common understanding of the situation can be achieved when different parties receive information about each other's activities and plans.

In the case of district heating, the demand for district heating is determined by external conditions, such as temperature and wind, calendar and time. SyncPower® calculates the forecast of steam consumption from the factors influencing demand and changes it as conditions change.

Once the forecast for steam consumption is known, the plant can plan the driving modes and selection of fuel optimally and prepare for - or, best of all - avoid possible boiler starts.

Forecasting electricity production and consumption is important for industrial plants that utilize different electricity marketplaces.

SyncPower® helps predict electricity production by providing the most accurate forecast of steam consumption and electricity production for the next few hours and the next days. The forecast adapts flexibly to changes. Variables can include changes in factory production plans and weather forecasts, equipment failures at power plant or factory, or even a significant change in weather phenomena in the next few hours. The changes in variables affect directly the forecasts and the changes can be sent automatically to different stakeholders, so that in exceptional cases, attention can be focused on those items which need immediate action.